Choosing the right electric tug or mover

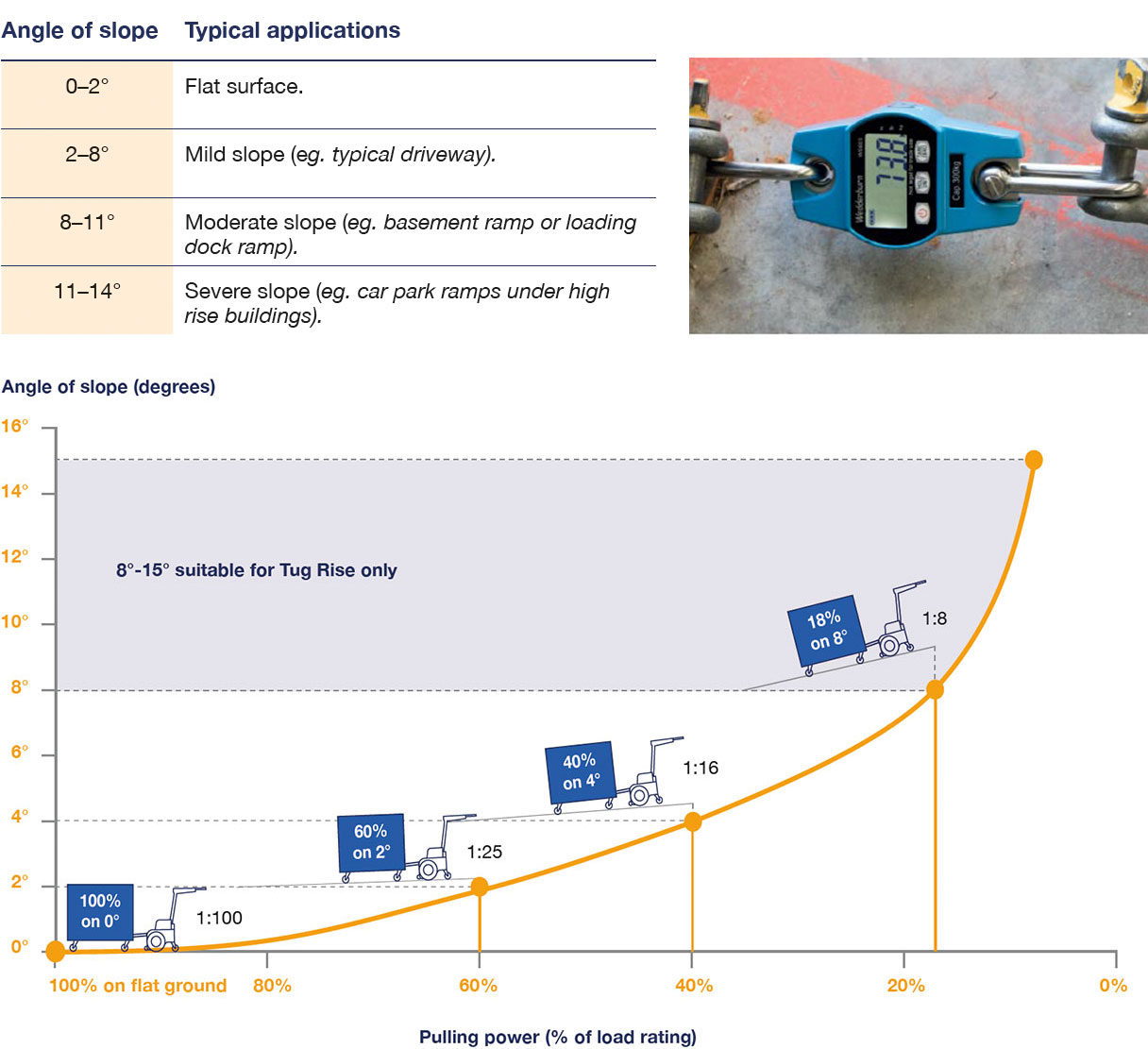

1 Determine the weight and incline of the load being moved

The nominal towing capacity of our tugs relates to the weight that can be pulled on a flat surface (with a friction coefficient of 0.5 such as dry concrete or bitumen).

The practical rule of thumb to determine which tug is right for your application is to get the pull force (in kilograms) required to start your load moving (on the worst case surface of your application) and divide it by 0.04. This will give you the pulling power required.

So, for example, if it takes 30 kg of pull force to get your trolley moving on your intended surface, divide this by 0.04 to identify the pulling power required of 750 kg, meaning that you will need a tug that can pull more than the Tug Compact (500 kg), and would need the power of a Tug Axis 1T, which will exceed your pull force comfortably.

Another way of thinking about this is that for every 1T of load to be pulled, the force to pull it will increase by 40 kg.

Measuring the pull force required to start the load moving can be done with a weight scale—of the type used to weigh produce at the green grocers, or the more modern digital luggage scales such as those shown in the photos above.

It is important to measure the pull force required on the worst case of your application. Perhaps a linen cart will need to follow a route that includes the flat internal hospital passageways on carpet, as well as an outside bitumen area with a 6 degree slope. Make sure you measure the worst case scenario—in this example, the outside inclined area when wet (to simulate the added slipperiness that occurs when raining).

A final "top tip": Measuring the incline can be done with a smart phone app. Go to your app store and search for ‘measure incline’ or ‘measure slope’ or ‘spirit level’ and you’ll have many options to choose from for both Apple and Android smart phones.

2 Determine whether it will be used in confined or open spaces

Please use the following guide to help determine the suitability for your application.

Please note: A ʻconfined spaceʼ refers to a small space with a single doorway (standard width of 820 mm).

| Suitable for confined spaces |

|

|

Tug Compact

|

Nimble and tiny. Smallest footprint and turning circle. Passes through a single doorway with ease. Excellent for moving stock trolleys inside and outside.

|

|

Tug Axis 1T and 2T

|

Tug Axis 1T and 2T models can fit through small office doorways with ease if the item being towed can follow it. Always lock the turret when not towing loads.

|

|

Tug Axis 4T / 5T

|

Tug Axis 4T will fit through a single doorway on slow speed and with its turret locked to allow it to be parked at the end of the day, but the Tug Axis 5T is slightly wider.

|

|

|

Gzunda Bed Movers

|

Excellent for indoor applications, lifts and most confined spaces. The machine does not drive laterally so it needs about 2x2 m to pivot in a circle when not attached to a hospital bed.

|

|

Gzunda Linen Mover

|

Excellent for indoor applications and most confined spaces. Its tiller arm can be folded to reduce length by a further 500 mm so it can be manoeuvred around corridors and parked easily.

|

|

|

Transpak Powered Trolley

|

Ideal for moving meal delivery systems or multiple boxes through corridors. Fits through single doorways in slow speed for easy charging or storage.

|

| Suitable for open spaces |

|

Tug Rise 1T

|

Large, high-traction forklift wheels make the Tug Rise a bit wider than the others (as it is designed for steep carpark ramps) so it won’t fit through standard doorways.

|

|

Tug Tough 10T

|

Perfect for moving loads weighing between 4-10 tonnes in open spaces. Can go through a single doorway for storage or charging.

|

3 Determine if the load will have existing hitch points

| Hitches to suit the most popular trolleys |

|

|

|

|

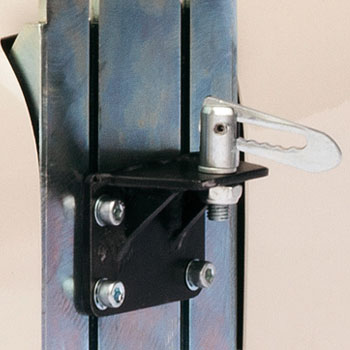

Pin hitch

|

Auto-latching hitch

|

|

| Hitches that adapt to different trolley designs |

|

|

|

|

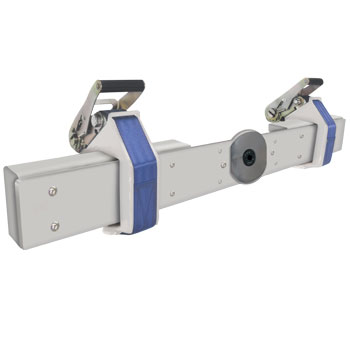

Clamp hitch

|

Flex hitch

|

Groove hitch

|

| Hitches for bed movers |

|

|

|

|

Flex hitch

|

Gripper hitch (various sizes available)

|

Ratchet hitch

|

| Hitches for bins |

|

|

|

Double wheelie bin hitch

|

660 and 1100 litre bin hitches

|

| Hitches for trailers, caravans and boats |

|

|

|

|

Tow ball A-frame hitch

|

Hydraulic arm lift hitch

|

|

For more information on hitches, visit out hitching and accessories page.

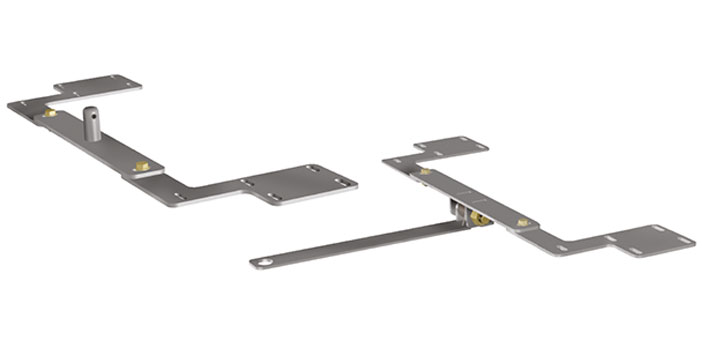

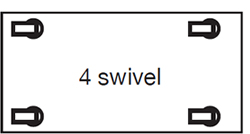

4 Determine the load's wheel configuration

Castor configuration will affect towing

Four swivel castors will not trail properly behind the towing unit—

they will cut corners rather than follow the unit. They will also tend

to 'whip'—to over correct any sideways displacement and sway

from side-to-side as they travel.

These problems become more acute if more trolleys are linked in a train. We offer fixed wheel

skate hitch (pictured) accessories to correct this problem for situations where it's not feasible to replace two of the four swivel castors on an existing trolley fleet.

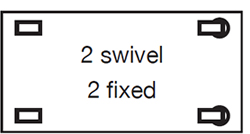

If two fixed castors are used at the rear of the trolley it eliminates the whip, and improves trailing and towing.

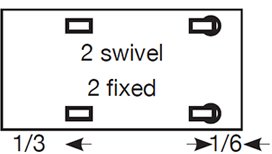

An ideal configuration is to mount 2 swivel castors 1/6 of the length of the trolley from the front of the trolley and two fixed castors 1/3 of the length of the trolley from the rear. This gives little whip, and good trailing. Note though, that such trolleys should not have a heavy load concentrated at the rear end or they will tip backwards.

|

Trailing |

Whip |

Stability |

|

Poor

|

Bad

|

Very good

|

|

Good

|

Least

|

Very good

|

|

Good

|

Little

|

Good

|